3D printed mechanical arm

The project is based on 3D printing and modifying The UnLimbited Arm 2.0 Alfie Edition arm for a 15 year old girl, Sabita.

I volunteered in this project from October, 2016 - April, 2017 in CMDN (Centre for molecular diagnosis), Kathmandu, Nepal. I continued working on this project during the summer of 2018 with other biomedical undergraduates.

The article about this project was published in the national daily: The Kathmandu Post.

Mentor: Brian Galloway

Members: Anuj Baskota, Ritwicq Arjyal, Roman Shrestha, Satyandra Jaysawal.

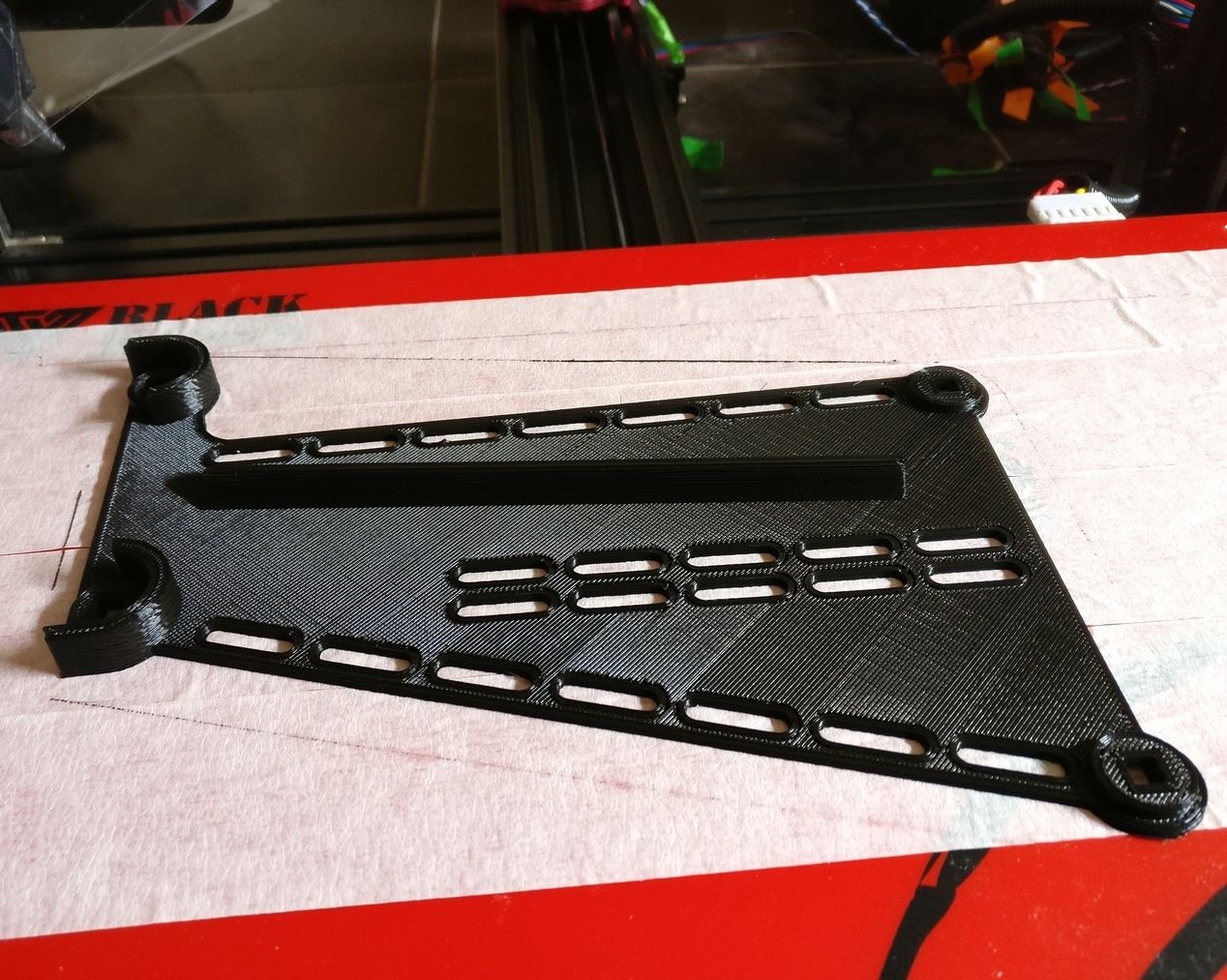

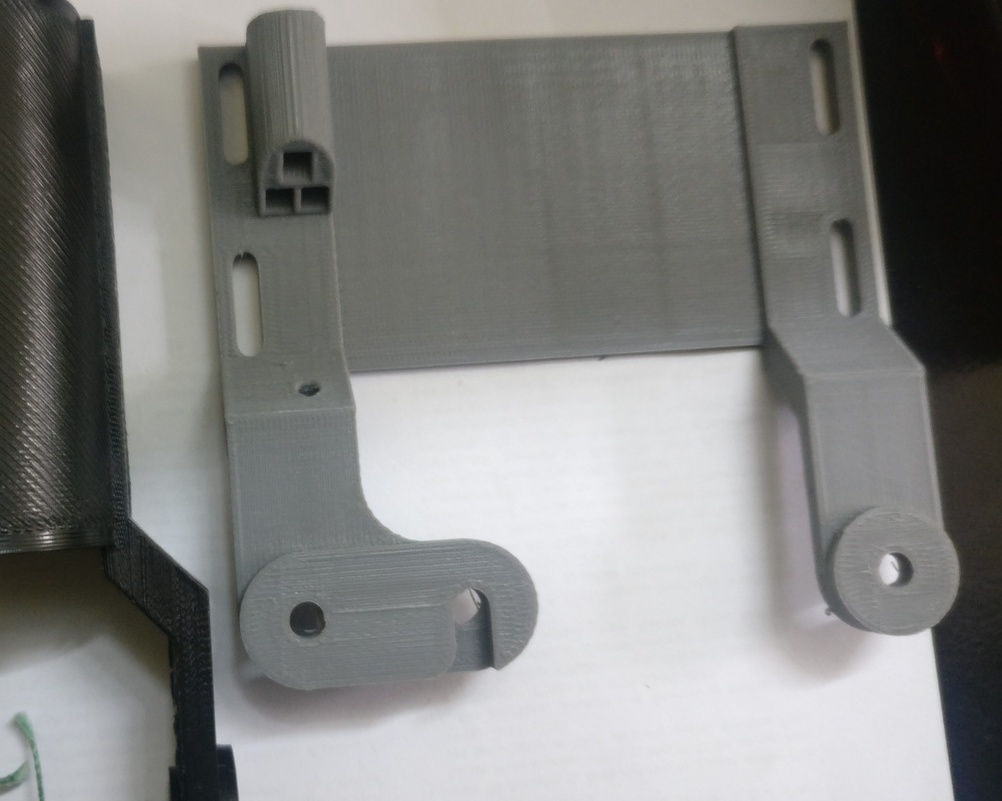

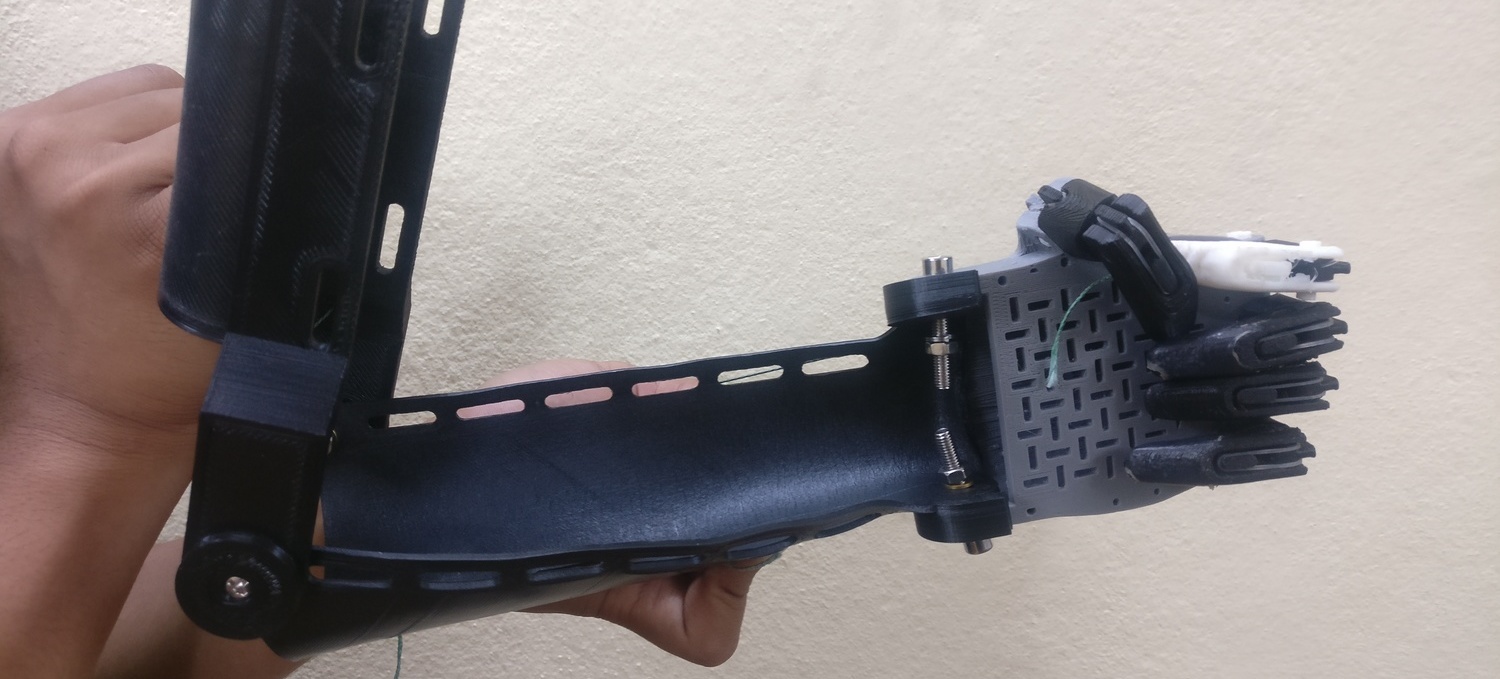

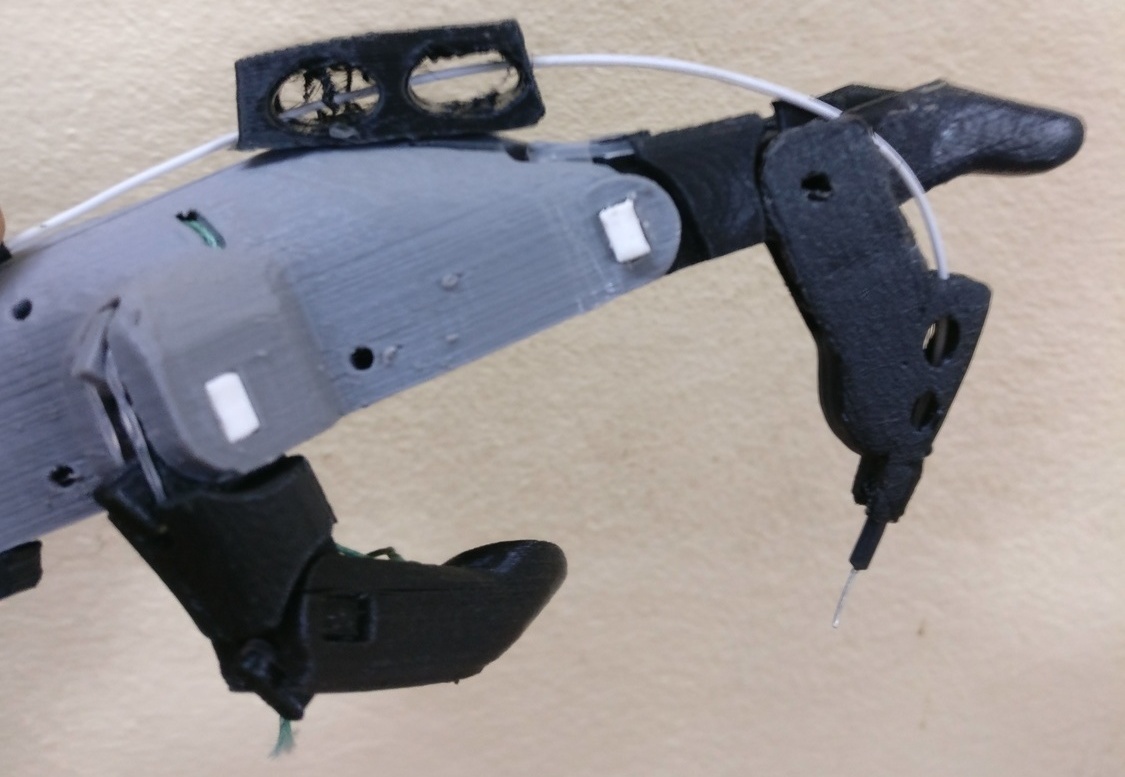

We decided to print The UnLimbited Arm 2.0 Alfie Edition for Sabita as it is a fully customizable and parametric arm. The 3D printed arm is comprised of the phalanx, the fingers, the palm, the forearm, the pins, the cuff and the jig. These are further supported by strings, elastics, and plastic for its functionality and strength. The arm can be customised to the specific requirement of the recipient using the thingiverse customizer.

We downloaded the .stl file of the hand and uploaded it on Repetier host. The hand itself cannot be printed as a whole-each part needed to be printed seperately and joined using 3D printed pins. The parts consisted of fingers, cuff, palm, forearm, and phalanxes. After several prints, we got the first prototype ready. Although the quality of the prints were not the finest, it was certainly a functioning prototype.

The arm operates by bending the elbow which in turn creates tension on the strings. Since the strings are tied to the fingers and there is tension on the strings, the fingers contract(bend) which would allow the patient to grab objects. The bending of the fingers decreases with the decrease in the bend of the elbow and vice versa. The elbow must be completely unbent for the fingers to return to its unbent state, thus, releasing the object . The elastic used in between phalanx and finger allows the fingers to return back to their original position. For smooth contraction and relaxation, there must be a minimal amount of friction between the plastic and the strings. The pins act as a fulcrum between the forearm and the cuff, the phalanx and the finger, palm and forearm. In addition to this function, the pins also fasten these parts together.

Prototype testing:

1. Mechanical testing: This included testing for its tensile strength and compression.

2. Thermal: Conducted prints in different extrusion temperature ( 170° C - 220 ° C ) and bed temperatures (20° C - 65 ° C )

3. Chemical: Exposed print parts in acetone, and ethyl acetate in vapour and liquid form.

After the consensus of the group, we invited Sabita to test the prototype along with her brother. The results were quite promising. She could hold a standard 750ml bottle but holding a pencil was not easy. She was happy with the standard design and the weight of the arm, but as for the dimensions, she had two requests:

- To decrease the forearm length by about 20 mm

- To increase the cuff length by about 20 mm

Two modifications had to be made on the arm as per Sabita’s requests. The changes were made again using the thingiverse customizer.

Though the 3D printed arm served its purpose, we realised the mechanism by which she could hold a pencil was still inefficient and had ample room for improvements. Our primary concern was the continuous requirement to bend the elbow in order to maintain the tension on the strings and consequently the fingers .

The solution was pretty obvious: all we had to do was maintain the tension on the strings. Also, there was a frequent slip of objects from the prosthetic hand due to low grip of the PLA (Polylactic Acid) fingers which was our other concern.

Additional Modifications:

For grip:

1. TPU (Thermoplastic polyurethane) : It is known as flexible filament. It enhanced the grip of the PLA fingers.

2. Latex Dip: Adding a layer of latex on the fingers increased the grip for holding the object. Consequently, holding things like pencils and bottles were easier.

For tension:

Sliding bolts: Different types of bolt depending on the size and the tension on the strings were used. This bolt is commonly used in doors and windows.

Fig: Left to right: Small bolt, half and half bolt and 100% no tunnel maximized strength bolt.

Adaptive Grips: With the few locking mechanisms we tried, we were certain of the PLA lock slots not being being able to hold the handle in place.The tension in the string placed a large amount of force to resist on the slit which caused it to break. So we decided to reduce the tension on the string itself using adaptive grips . It is basically a 3 sesaw system that helps to grip object using less force as the fingers try to adjust to the shape of the object.

Modifications to improve the hold of pen cartridge:

Finger cap: Maintaining the tension and keeping the arm lightweight was a challenge so we decided to take a relatively different approach on holding the pencil. We decided to add a clip -on to a single finger so that there would not be problems regarding tension. We used a .stl file called “ THE SOLO PEN” and modified it to our needs using MeshMixer and the idea worked fine until we actually tried writing with it and discovered that it was not stable.

Finger cap with a pam stabilizer: The finger caps and palm stabilizer was the first solution that actually worked and was relatively easy to write with despite having a prosthesis on both arms. The finger cap would hold the pen cartridge near the tip of the pen and the palm stabilizer would hold the end of the cartridge and on doing so would create an arc and which caused the finger with the finger cap to lose its mobility. There was a screw at the end of the palm stabilizer with the purpose of moving the pen cartridge to either increase or decrease the arc.

Knucles: This modification was easy to put on and easy to take off. So the finger caps along with the knuckles was our go to option. First we tried on the two finger knuckle but that was still unstable and needed a more rigidity. So, we modified the knuckle for 4 fingers and attached the finger caps which worked better. This was our best solution so far for holding the cartridge of the pen.

The arm was handed over to Sabita with some of the modifications that she preferred. It is amazing how technology can make a huge difference in someone's life with just a little effort.

We definitely faced several electrical as well as mechanical issues with the prints and the printer. Here are some of the print problems and what worked for us.